UK Metro

UK Metro

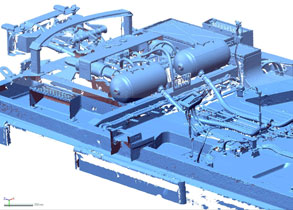

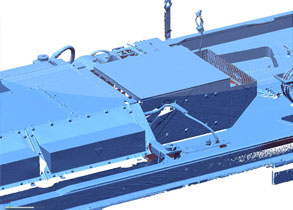

“We’ve recently started using the Surphaser to scan the underside of trains for a large UK metro service provider. Previously the scanning activity took 2 days to recover the data from the underside and a further 5-6 days from aligning the data into an accurate mesh model. Since we started using the Surphaser, the scanning time has been reduced to a few hours, and the post-processing now takes only 1 day. Not only is there a huge time saving, but the quality of the data is significantly higher. The massive focal depth of the Surphaser means that from a single position we can now collect data that would have required 30 or more scans. Also occlusions and shadowing are minimised by the virtue of the ‘true’ line of sight nature of data collection. Surphaser is also able to collect data from the shallowest of scanning angles, only 5 degrees. Shallow angles combined with the depth of focus range and line of sight collection means acquiring large, complete, and highly accurate meshes is easy.”

– Simon Stone Mech Innovation Limited