Atlantis Turbine

Atlantis Turbine

Scan Details:

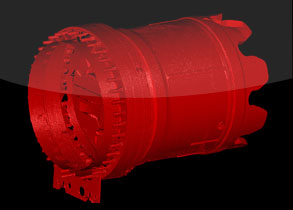

- Scanning took approximately 5 hours for 16 scans. I'm sure this could be done quicker with experience as we were just getting used to the system.

- The data was processed to .ptx files with Surphaser software and then imported into Cyclone to register cloud to cloud.

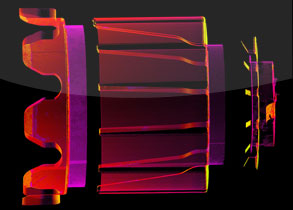

- The main turbine was modeled in Inventor 2013 using the native Autodesk Pointcloud support.

- The female stab connector inside was meshed in Geomagic and exported as an .stl.

Specifications:

- Scanning took approximately 5 hours for 16 scans. I'm sure this could be done quicker with experience as we were just getting used to the system

- The data was processed to .ptx files with Surphaser software and then imported in to Cyclone to register cloud to cloud.

- The main turbine was modelled in Inventor 2013 using the native Autodesk Pointcloud support.

- The female stab connector inside was meshed in Geomagic and exported as an .stl.

- Processing and modelling took approx 8 days.